HFP Vulcanizing Splice Fabric Primer

FUSION

HFP Vulcanizing Splice Fabric Primer

- Compatible with major conveyor belting

- Excellent brushability

HFP is a one-part coating for RFL treated fabric that enhances adhesions in vulcanized belt splicing. It is designed for use as a reactive bonding agent between bare fabric surfaces and uncured splice materials.

Why Is Almex Different?

- For RFL treated fabric to enhance adhesion for uncured splice materials

- Compatible with and exceeds many belting manufacturer specifications

Features and Product Information

Features

- Prepares the clean work surface for tackifying and increases the bond

- Tested for compatibility with all major conveyor belting manufacturer specifications

- Brush-able consistency for ease of application

- Good penetration into RFL treated fabric

- Use for Natural Rubber (NR), Polyisoprene (IR), Styrene-Butadine (SBR), Polybutadiene (BR), Polychloroprene i.e. Neoprene (CR) rubber belt splices

- Flammable

Product Information

Properties:

Rubber Colour: Black

Base Polymer: Mix of Polymers

Solids (wt.): 20-25%

Formula: Xylene

Calculated Coverage: 13.4 M² (144 ft.²)

Flash Point: 26 °C (79 °F)

Shelf Life: 6 Months at 21 ºC (70 ºF) or 12 Months at 10 ºC (50 º).

Specifications

| Product Code | Weight (Metric/Imperial) |

|----------|------------------|-----------------|

| AA-HFP-Q | 750 gr / 1.7 Lbs. |

Accessories

Fabric Belt Splicing Tool Kit

Fabric Belt Splicing Tool Kit

Smooth Flat Roller - 2" x 0.5"

Smooth Flat Roller - 2" x 0.5"

Smooth Flat Roller 2" x 2.5"

Smooth Flat Roller 2" x 2.5"

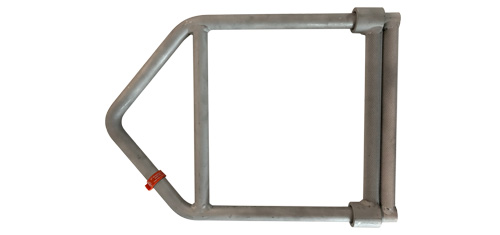

Belt Stripping Buckle 10"

Belt Stripping Buckle 10"

Gripping Clamp with Pivoting Head

Gripping Clamp with Pivoting Head

Related Items