- Sophisticated air-brakes with built-in redundant backup.

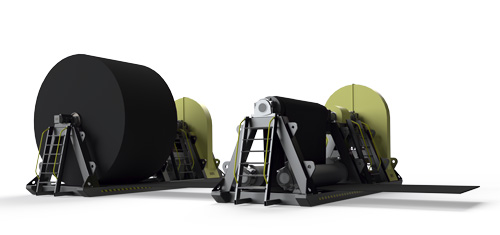

Almex equipment has a reputation of being designed for harsh environments and Almex Belt Brakes are the most sophisticated and state of the art in the world. By the very nature of a belt brake, it must prevent catastrophic events and so only the highest quality components are used with redundant backups designed into the units.

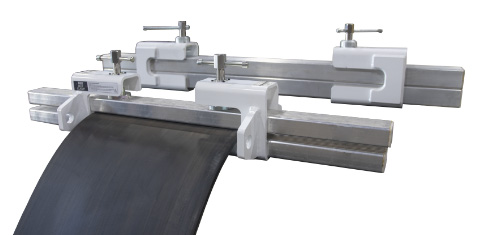

Air brake units allow for careful and controlled descent of the belt. Units can be supplied in tandem to ensure a safer installation. The brakes are engineered with higher safety factors and manufactured to the highest level of accuracy as they are a critical component to a safe belt installation.

Belt brakes are supplied with dual pressure bags to provide redundancy during operation. The frames are welded and fabricated from high strength steel by Almex’s experienced welders to the highest standards. The bolts are cold rolled from high tensile steel to provide the strongest possible bolts.

Belt Brakes can be operated manually or as part of the integrated systems. With the optional speed sensors mounted, they will transmit information to the ALMEX INTEGRATED CONTROLS to detect “runaway” scenarios and arrest the conveyor belt by activating the Belt Clamps. Wireless tablets can be added which allow for remote and safe operation of the units.

The units shown here will generate in excess of 200 tones of clamping force each. The Belt Brakes are manufactured to such high-quality standards that they come with a lifetime frame warranty from Almex.

The number of clamps and the configurations can be modified based upon the installation requirements for control and safety.

- Almex uses only drives, couplings and frame construction that exceed standards to ensure the safety of the operators and protect your infrastructure.

- Each component has extensive finite element analysis (FEA) calculations done to ensure it can withstand the forces it will encounter during operation.

- Almex does not outsource the manufacturing of components. In fact even the bolts are cold formed internally.

Features

- Belt brakes can be manual or have sensors built in to detect “run away” scenarios and arrest the conveyor belt release

- Belt Clamps are available with a Hydraulic/spring design which will clamp shut on the conveyer belt securing it safely in the case of a run away belt

- Wireless tablets can be added which allow for remote and safe operation of the units

- Air brake units allow for careful and controlled descent of the belt and units can be supplied in tandem to ensure a safe installation

- Almex uses only drives, couplings and frame construction that exceed standards to ensure the safety of the operators and protect your infrastructure

- Commissioning and start-up services are available

Applications for belt brakes have unique requirements based upon the length of the conveyor, the width of conveyor belt, the slope of the belt and the amount of conveyor being installed. Almex’s engineers undertake detailed finite element analysis and strain calculations to ensure that units able to withstand the loads.

Air Brakes are designed and manufactured according to the specifications required. Please contact your Sales Representative to discuss.