- One-Time or Continuous remote operation options

- Non-destructive scanning

- Operational mitigation - detect issues early

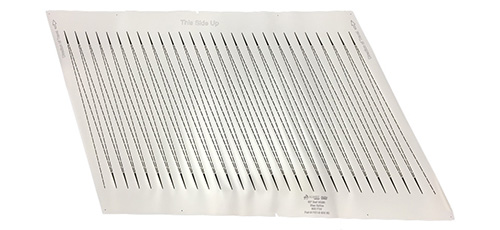

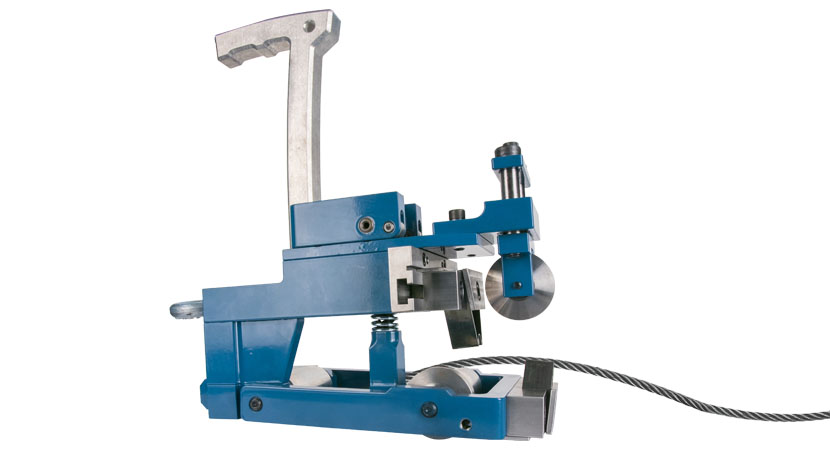

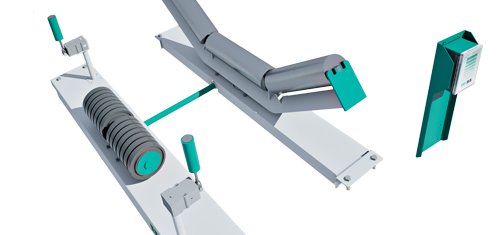

The EMSYS BeltGard Systems uses MFL technology to provide an advanced non-destructive belt scanning system that can determine cable damage, splice layout, splice deterioration and corrosion in any steel cable belting.

BeltGard Systems uses rare earth magnets that magnetize the steel cables within the conveyor belt and the sensor head and then a high-speed processor reads the magnetic flux from the damaged/cut/corroded cables.

BeltGard works for any steel cable belt manufacturer and any belt thickness or belt speed. The system provides alerts based on various tolerance points set to provide a Non-Destructive Test (NDT) solution and early warning of any potential belt failures.

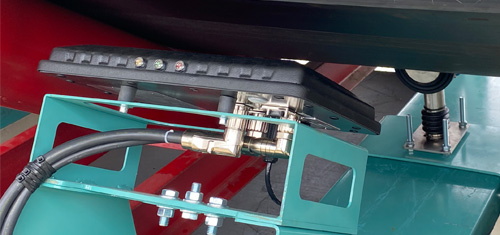

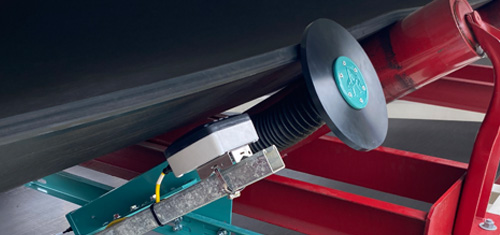

BeltGard 3.O is a permanently installed version with high-speed, on-board processor that provides real-time high-speed continuous scanning. The unit is constantly comparing the historical scan to current events to detect events in real-time and prevent catastrophic failures.

For permanent monitoring support, Almex Global Services staff can permanently mount the equipment and remotely monitor the conveyor belt anywhere in the world through our Remote Monitoring Centers.

The Almex BELTGARD System is an advanced non-destructive belt scanning system that can determine damage, splice layout, splice deterioration and corrosion in any steel cable belting.

Features

- Monitors every revolution, comparing data to baseline

- On-demand automated reporting of all events seen within the conveyor system

- Email reporting a weekly/daily/hourly basis, custom report formats available on request

- System integration into the mine PLC is possible through dry contacts, relays, and volt free interfacing

- Available signals: Watchdog/health, Alarm & Trip

- Automated belt “parking” to allow specific events to be placed within a maintenance bay for inspection

- Multi-level password protection and usernames

- Damage event history for the last 24 hours

- Quad core processor with up to 512 GB storage

- Operating temperature –20 to 70 degrees Celsius

- Battery backup and orderly shutdown 20 -60 seconds

- Wireless 802.11b/g/n and Bluetooth 2.1

- Cellular modem for remote connectivity

- Modbus & ethernet ports & HDMI & USB connections

- Ability to view results safely away from the conveyor via Bluetooth and Wi-Fi connectivity