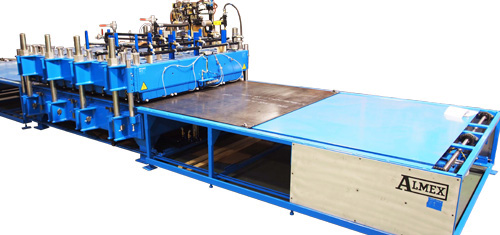

- For Rubber Conveyor Belts

- For Rubber Sheet and Screen Goods

- Minimal Press setup time required

Since their introduction in 1966, the hinging Almex ‘BMS’ series of presses have been a remarkable innovation and one which … you can’t afford to ignore.

The key to the Almex success story lies in the exclusive pressure bag system which provides the uniform pressure so essential in a curing or laminating press. The numerous benefits of our vulcanizing system are tied to this one critical design concept. We incorporate either an inflatable pressure bag or membrane to generate the platen pressure which reduces many of the costs and difficulties encountered on conventional hydraulic manufacturing presses.

Hundreds of customers have realized the benefits gained by eliminating the massive hydraulic cylinders inherent to the conventional manufacturing press which also provides ease of operation.

All of this means the cost of an Almex BMS is substantially lower than that of comparable size hydraulic presses.

These benefits, coupled with the added features of reduced shipping and assembly costs, and the elimination of expensive foundation pits, provide good reason for investigating …… The ALMEX system.

Combining technologies from multiple different disciplines allows Shaw Almex to provide unique, innovative and cost-effective solutions to a multitude of different press requirements. Add in our customer service and support, and you have a “win-win” partnership with Shaw Almex, their designers, and field technicians.

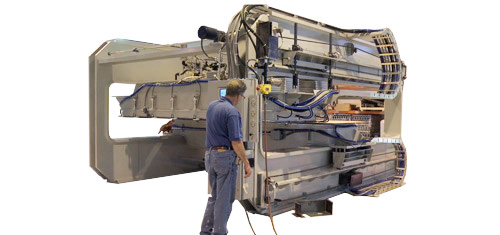

This approach to customization is illustrated by the new hybrid press delivered to Beltservice Corp’n in 2019 shown here.

In the past, changing the daylight setting on a BMS press was slow and cumbersome.

In response to the customer requirement, ALMEX designed a new press which combined the traditional pressure bag (for uniform pressure) with a combintation hydraulic/screwjack system to provide infinitely adjustable daylight (max 16”) controlled through a Touchscreen interface on the control console.

Daylight opening can now be adjusted in a matter of seconds.

Features

UNIQUE HINGING UPPER FRAME

There is full access on all three sides of lower platen, making mold plates easily accessible to change, clean or reload when fabricating specialty profiles. This accessibility also means the BMS is suitable when special forms are required.

TWO TYPES OF PLATEN CONSTRUCTION OFFERED

Steel platens offer the maximum in durability and provide the optimum finish. Aluminum platens are available when a smooth finish is not critical (i.e. with molds, etc.) and have the added benefit of requiring approximately half the energy to heat compared to steel platens.

PRESS DESIGN PROVIDES LOW COST INSTALLATION

The full weight of press is evenly distributed over two steel girders running the complete length of the press; a unified design that makes the BMS shipable in one piece, saving shipping costs and on-site assembly time.

The BMS press can be located anywhere in the factory on a standard concrete floor. Since structural modifications are not required to support the press, subsequent relocation is easily achieved.

INTERLOCKING FUNCTIONS

All BMS press functions are interlocked for maximum safety. The hinged upper frame is hydraulically pinned when in the open position meaning operator error and product damage is minimized.

FULL INSTRUMENTATION

All pressure, temperature readings and time functions are controlled from a centrally located control panel. Pneumatic controls are press mounted and remote operation is optional.

VARIOUS HEATING OPTIONS

Steel platens can be heated with steam, hot oil or electric calrod heaters.

Aluminum platens can be heated with steam, hot oil or electric blanket heaters.

Membrane presses can be heated with hot air heaters or infrared heaters.

Product Information

Combining technologies from multiple different disciplines allows Shaw Almex to provide unique, innovative and cost-effective solutions to a multitude of different press requirements. Add in our customer service and support, and you have a “win-win” partnership with Shaw Almex, their designers, and field technicians.

Interested? Fill out our Industrial Press Inquiry Questionnaire and email it to us to start the discussion.

PLATENS

Platens are available in two different types of construction:

- One piece, hot rolled steel slab, gun-drilled for the heating medium.

- Laminated aluminum construction incorporates rolled aluminum plates which contain the heating fluid and cooling medium if required.

FRAME

Welded steel frame construction, designed for operating pressures up to 200 p.s.i. (14 kg/cm2). The hinging upper frame opens hydraulically to angles up to 85 degrees.

The BMS model accomodates platen widths up to 80 inches (2030 mm) and press lengths up to 48 feet (16 m) in 12 foot (4 m) increments.

All press functions are interlocked to provide maximum operator and product safety. The press frame is manufactured in one piece complete. The Maximum daylight opening between platens is 12 inches (300 mm). The BMS is available in down-stroking or up-stroking configurations.

PRESSURE SYSTEM

The unique Almex pressure bag is protected from heat degradation by a water cooled insulation package. Membrane installations utilize high-temperature elastometrics for the inflatable member. Pressure system does not include air compressor or air receiver.

OPTIONAL EQUIPMENT

Edge Irons

A hydraulically actuated edge iron system may be mounted on the front and rear of the press lower frame. Edge Irons are ideal for materials that become semi-liquefied at elevated temperatures.

Platen Cold Ends

For manufacturing continuous products, the heating platens may be equipped with a water cooled cold zone, eight inches wide (200 mm).

Automation

Press functions can be automated to speed up the cure cycle, and maximize productivity.

Control systems may be either PC or PLC based. Customized software allows graphic displays, data acquisition and logging and networking.

Remote Supervisory Stations allow managers and supervisors to interface with the system from the convenience of their office.

Clamp and Stretcher Units

When it is necessary to pre-tension the elastic product prior to curing, a mechanical stretcher unit and a clamp unit can be positioned at each end of the press. Clamp and stretchers can be tilted to a maximum of 45 degrees from the horizontal. Uniform tensioning across the belt width is provided by hydraulically driven screw jacks. Automatic measurement ensures repeatability and consistency with the tension.