- Alerts can be set up to alert the operator and/or stop the belt

- Stopping a belt when a rip first occurs helps prevent catastrophic issues

- Works with LSRS for redundant rip monitoring protection

Belt conveyors are subject to damage (longitudinal belt rips) through the impact of foreign objects at the loading and discharging area, or edge damage from conveyor belt mis-tracking. Conveyor belts that do not have antenna installed or have antenna that have failed due to damage, are at risk of catastrophic rips and damage. Until now there hasn’t been a reliable solution to prevent that loss.

The EMSYS WSR system relies on embedded RFID Tags inserted into the belt to provide a reference home position in the conveyor belt. The belt is then operated for several revolutions taking measurements every inch of the conveyor width as a baseline. If the belt is ripped longitudinally the width of the belt will change and trigger a signal to stop the conveyor belt. Additional Alarm parameters can be added such as excessive or continuous mis alignment/tracking of the conveyor belt or to detect edge damage. These alarms can be used to alert the operator at the belt or on a remote device such as a smart phone or tablet using WIFI.

The WSR does not require installed loops and can be used on both steel cable and fabric belts, of any length. The system and is UL and CE approved.

- Does not require installed loops

- Suitable for any type of belt- steel cable or fabric

- Suitable for any length of belt

Features

CONTROL UNIT

The processor is an ATEX-certified, state-of-the-art Allen Bradley PLC unit that is able to record multiple revolutions of data. It interfaces with the mine PLC or SCADA System.

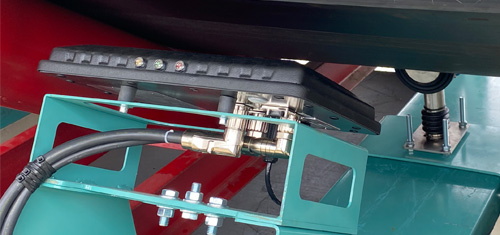

RFID READER

The RFID Reader detects embedded RFID tags that provide reference points to the WSR system as it learns and stores the width of the conveyor belt for its entire length. This data is compared to real-time data in order to detect any rips or edge damage.

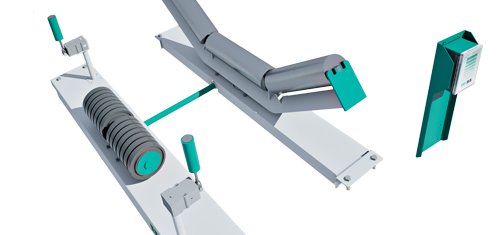

SYSTEM PRINCIPLES

When a conveyor belt is ripped due to a foreign object it will exhibit one of two different states – spreading or shearing. The WSR system utilizes an offset idler in front of the system to amplify these actions and accurately detect a rip. Because it doesn’t rely on antenna, it will detect a rip immediately after it begins due to the change in the width of the belt.

BELT WIDTH MONITORS

Mounted on either side of the conveyor system are linear encoders that telescope in and out and work together to create a baseline of the width of the entire belt. If necessary, the belt can be re-trained again to record any changes in the belt.

DATA APPLICATION

The WSR system provides a graphical display of the entire conveyor belt both in the control room or remotely on a smart phone or tablet. Conveyor belt data, alerts and stoppages are all displayed.

DETECTS RIP DAMAGE

No other rip detection adds the additional benefit of edge damage detection. The WSR compares the conveyor belt to stored data and measurable wear is detected and transmitted to the operator and the mine system. Edge repair is extremely costly and difficult to repair and the EMSYS WSR can detect this damage before it becomes a problem.