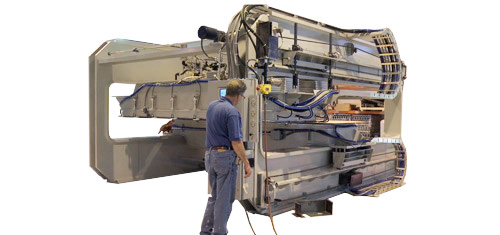

The Almex RCTD Mat press offers a unique pressure bag press system.

The key to our innovation is the ALMEX pressure bag principle. This patented system of utilizing an inflatable rubber pressure member to develop perfectly uniform pressure, revolutionized the design of flat presses.

Traditional presses which utilize large, high pressure, hydraulic rams to generate platen pressure, had many drawbacks compared to the pressure bag which applies uniform pressure required to cure, laminate, vulcanize or mold the end product.

These benefits, coupled with the added features of reduced shipping and assembly costs, and the elimination of expensive foundation pits, provide good reason for investigating …… The ALMEX system.

Features

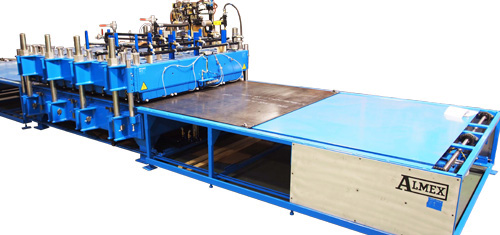

Press Features:

Every ALMEX RCTD Mat Press is equipped with full instrumentation:

- All pressure, temperature indication and time functions are controlled from a centrally located control panel.

- Pneumatic controls are press mounted.

The Mat Press design provides low cost installation:

- Full weight of press is evenly distributed over two wide steel plates which run the complete length of the press.

- The press can be located anywhere in the factory on a standard concrete floor. Since structural modifications are not required, subsequent relocation is easily achieved.

Daylight adjustment is quick and easy:

A series of blocks or spacers, with varying heights are used to adjust the daylight opening. Press is opened between cures, to the preset opening, by sliding the daylight adjustment block out from under the cross beams with a hydraulic cylinder and then raising the frame by a hydraulically driven system.

Lower steel platen only and top frame mounted diaphragm which is designed to withstand the cure temperatures.

Teflon release agent:

When there is a danger of the cured product sticking to the platens or the diaphragm, and automatic tensioning system is installed to support a Teflon coated fiberglass belt.

Product carrier:

When carrying thin rubber sheets or other similar materials with low tensile strengths, a conveyor system is installed to move the product through the press. This product carrier is power driven, and includes preparation tables at each end of the press.

Rubber Sheet – Uneven Gauge:

The most innovative development for the RCTD Mat Press models has been a high temperature, pressure diaphragm which is installed on the upper frame in place of the usual heated platen. The diaphragm, when inflated, guarantees uniform pressure on rubber products with irregular surfaces. One typical application required a diaphragm to vulcanize a rubber sheet to the back of carpets.