- Compact Design

- Maintenance-free

- Continuous Measurement

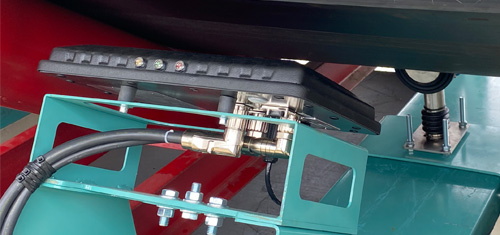

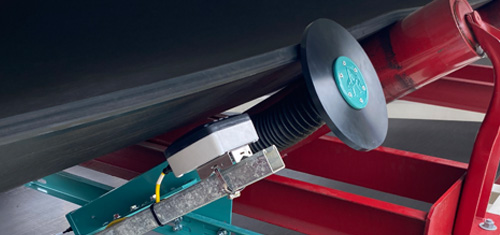

The Misalignment Transducer MT is a compact an rugged measuring device to determine the misalignment of conveyor belts. The MT was designed for harsh conditions in the mining and other industrial sectors. The rugged design, easy integration into existing belt conveyors and simple installation combined with the maintenance free operation characterizes the MT.

- Compact design

- Maintenance-free

- Continuous measurement of belt-position

- Applicable for extreme conditions simple integration into plant- and process automation systems

- Convenient installation

Features

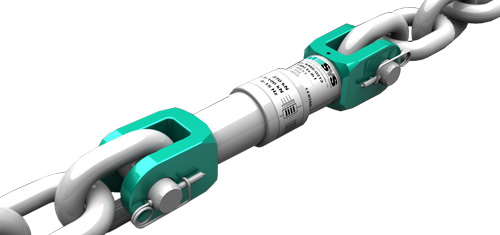

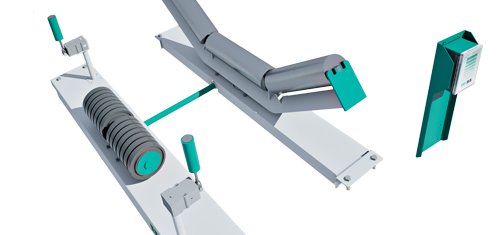

The misalignment transducer MT consists of the tuning angle transmitter DRS and the touch roller. The tuning angle transmitter is compounded by its housing, the inboard rotary element, the evaluation electronic and the return spring. The output of the evaluation electronic is an opto-decoupled signal of 5 Hz to 15 Hz according to the measured angle in the range of 0° to 130°. For the continuous tracking of the belt position the touch roll shall permanently be in contact with the belt edge which is realized by the return spring. If an application requires the polling of a specific angle the DRS is also available with a contact output.

Input voltage : 12 V DC

Power consumption : ≤ 20 mA

Measurement range : 130°

IP-Code : IP 65

Temperature : -20°C till +60°C

Design : Standard and ATEX [Ex I M2 EEx ib I ]