The Almex membrane RCTD press offers a unique membrane press system.

The key to our innovation is the ALMEX pressure bag principle. This patented system of utilizing an inflatable rubber pressure member to develop perfectly uniform pressure, revolutionized the design of flat presses.

Traditional presses which utilize large, high pressure, hydraulic rams to generate platen pressure, had many drawbacks compared to the pressure bag which applies uniform pressure required to cure, laminate, vulcanize or mold the end product.

These benefits, coupled with the added features of reduced shipping and assembly costs, and the elimination of expensive foundation pits, provide good reason for investigating …… The ALMEX system.

Features

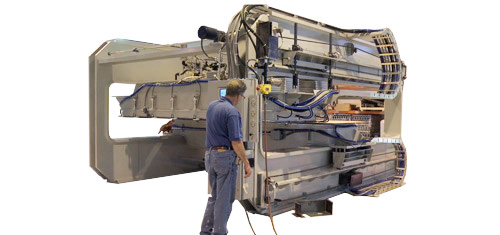

Production Belt Repair Press The RCTD models' top feature is their versatility. By custom designing these presses to suit individual customer requirements, the simple RC press first produced in 1965 has evolved into a highly sophisticated manufacturing press.

Now Almex Group is able to offer a manufacturing press with intermediate platens for increased productivity.

Press Features:

Every ALMEX RCTD Membrane press is equipped with full instrumentation:

- All pressure, temperature indication and time functions are controlled from a centrally located control panel.

- Pneumatic controls are press mounted.

Press design provides low cost installation:

- Full weight of press is evenly distributed over two wide steel plates which run the complete length of the press.

- The press can be located anywhere in the factory on a standard concrete floor. Since structural modifications are not required, subsequent relocation is easily achieved.

Daylight adjustment is quick and easy:

A series of blocks or spacers, with varying heights are used to adjust the daylight opening. Press is opened between cures, to the preset opening, by sliding the daylight adjustment block out from under the cross beams with a hydraulic cylinder and then raising the frame by a hydraulically driven system.

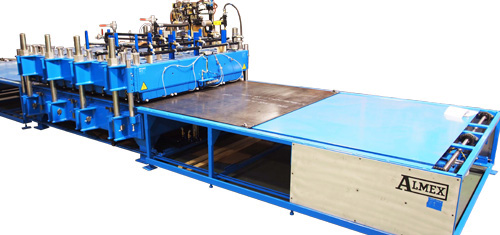

Shaw-Almex offers two different types of platen construction:

- Steel platens, for conveyor belt manufacturing.

- Flexible aluminum plates for conveyor belt reconditioning and repair.

**Product carrier (optional): **

When carrying thin rubber sheets or other similar materials with low tensile strengths, a conveyor system is installed to move the product through the press. This product carrier is power driven, and includes preparation tables at each end of the press.

Product Information

SPLICE

Allows longitudinal splicing, to produce one wide belt from two narrow belts.

FABRICATE

Vulcanize/fabricate/install profiles on slab belts, such as Chevrons, cleats and V-guides.

REPAIR

Longitudinal rips in conveyor belts.

Interested? Fill out our Industrial Press Inquiry Questionnaire and email it to us to start the discussion.

Laminating:

When a manufacturing operation requires heat and pressure to set or cure an adhesive in a laminated product, the ALMEX RCTD belt vulcanizing press is ideal. The sensitive nature of the product means uniform pressure and temperature are critical. One such application involves the lamination of aluminum panels to a Balsa core, in sizes up to 10 ft. by 20 ft. (3 m X 6 m) in one cure.